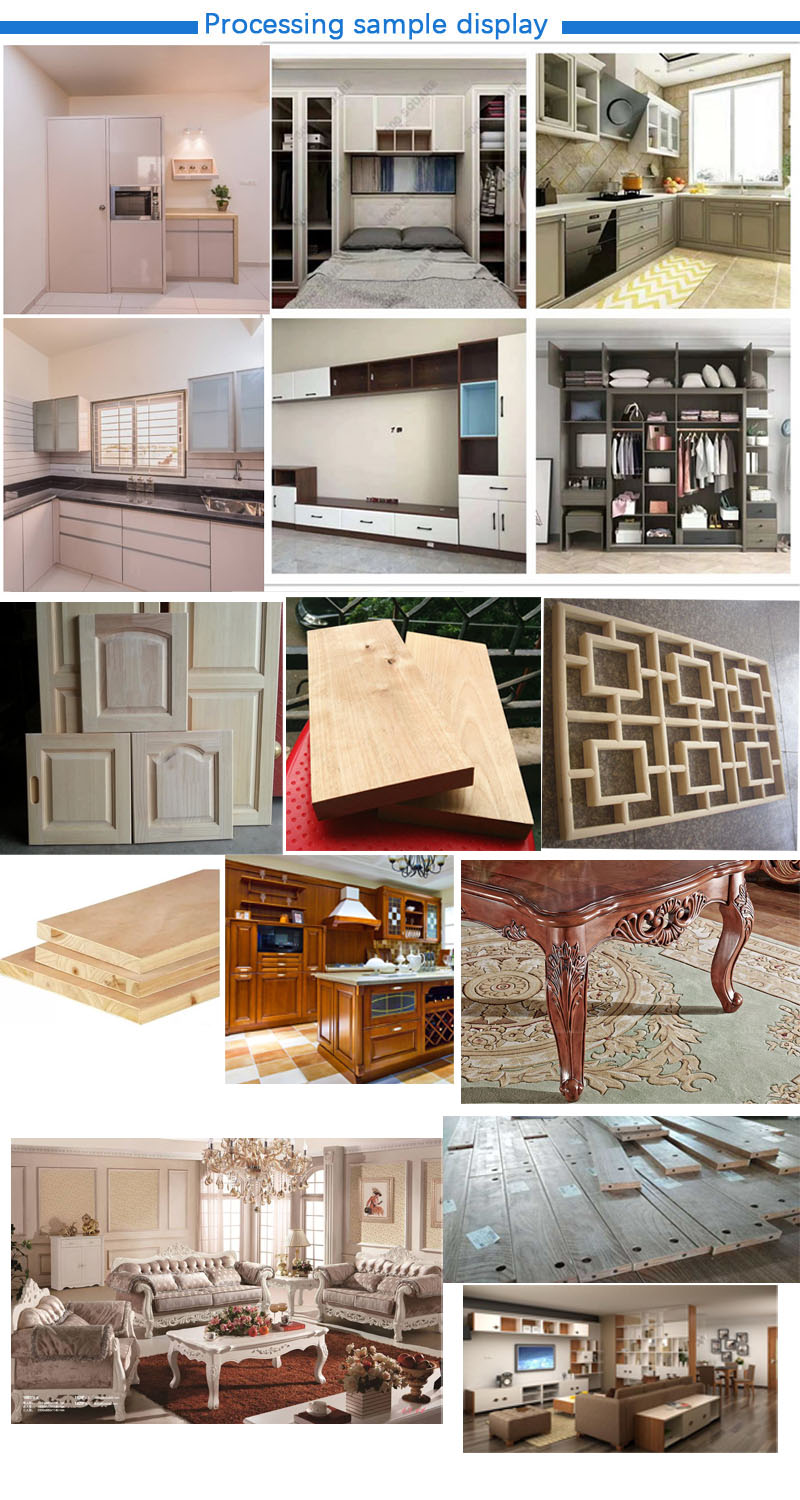

cnc wood engraving machine with high quality

Date:2022-02-28

1325 wood door engraving cnc machine1325 4 axis wood cnc router

A woodworking engraver is an electronic device used to create designs and shapes on wood. They come in a variety of different sizes and can be used to create a variety of wood carvings.

Wood carving machines work by using a variety of different tools to create a desired design or shape on wood. 3 axis wood 1325 cnc routerThe tools are attached to a moving arm controlled by a computer. This gives the wood carver complete control over the carving process.

CNC woodworking cutting machine: how to choose the right one:

1). The quality and performance of the spindle motor: The spindle motor is generally not covered by the warranty, and the spindle motor works continuously for a long time. If the spindle motor is not good, it will also affect the use of the engraving machine.

2). The function of the woodworking engraving machine: the spindle motor of the engraving machine is divided into high power and low power. Some low-power engraving machines are only suitable for the processing of two-color plates, architectural models, small signs, three-dimensional handicrafts and other materials. This technology has been popular for a period of time, but the engraving power is too small, and its application range is greatly affected. The other is a stone engraving machine with a high-power spindle motor. This kind of engraving machine is mainly divided into two categories: 1. Woodworking engraving machine with large working size: the working size is generally more than one meter, but the accuracy of this kind of engraving machine is generally poor; 2. The working size is moderate and small wood engraving machine : This engraving machine is generally used for fine processing and organic sign making.

3). Spindle motor speed regulation range: the general speed regulation range is several thousand revolutions per minute and 30000 revolutions per minute. If the speed is not adjustable or the adjustable range of the speed is small, it will affect the application range of the wood engraving machine, because different materials must be engraved with different engraving head speeds.

4). Body manufacturing process: When the high-power wood engraving machine works, the body must be precise and stable. Therefore, long-term high-power engraving requires a casting bed or at least one casting table to ensure its machining accuracy and stability.

5). Control system: The controller is generally divided into two categories: the first type of controller is only used for driving, and all the calculation work is done by the computer. When the wood engraving machine is working, the computer is in a waiting state and cannot be typeset. Another type of controller is controlled by a single-board computer or a single-chip microcomputer. This controller is actually a computer, so as long as the engraving machine starts working, the computer can immediately perform other typesetting work, especially when engraving for a long time. The advantages are particularly obvious.

6). Quality and precision of screw and guide: Screw and guide are also an important part of wood engraving machine. A good lead screw and guide rail are the guarantee of the precision and performance of the engraving machine during long-term use.Jinan M-Shine Technology Co. , Ltd.

Address: 3-1405 Room, Dongdu International Plaza, Industrial North Road, Licheng District, Jinan City, Shandong, China

Factory Address: 800 meters north of the intersection of Airport Road and Wenliang Road, Licheng District, Jinan City

Mob:+8618766144006(stone) Mob:+8615990994941(leo li)

web:www.m-shine.com

https://mshinetech.en.alibaba.com

Email:info@m-shine.com leoli@m-shine.com